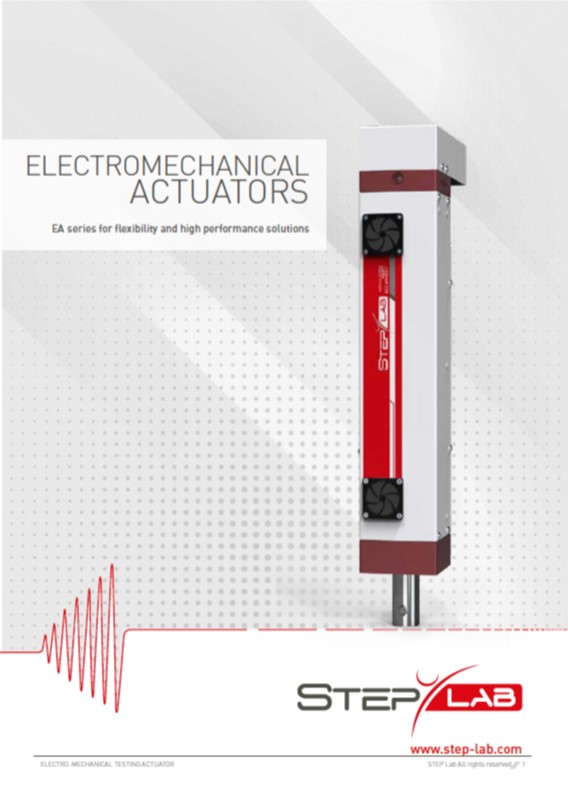

STEP Lab was founded in 2011 as a manufacturer of machines for mechanical testing. Today STEP Lab is a company that produces and sells electromechanical and electrodynamic systems for static, dynamic and impact mechanical tests.

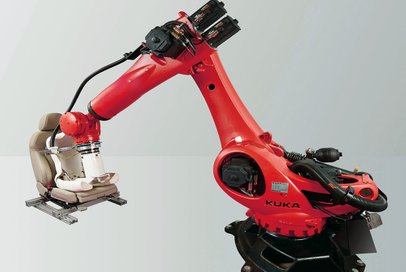

The product range of STEP Lab is divided into the following areas: Electromechanical actuators based on ball screw, Electrodynamic actuators based on linear motor technology, Drop Towers, Climate Chambers and Robot Based Systems.

All our machines are based on electrical actuation and are managed by the same controller and software interface Test Center, the result of constant implementation and optimization.

STEP Lab is also specialized in the realization of customized testing systems.