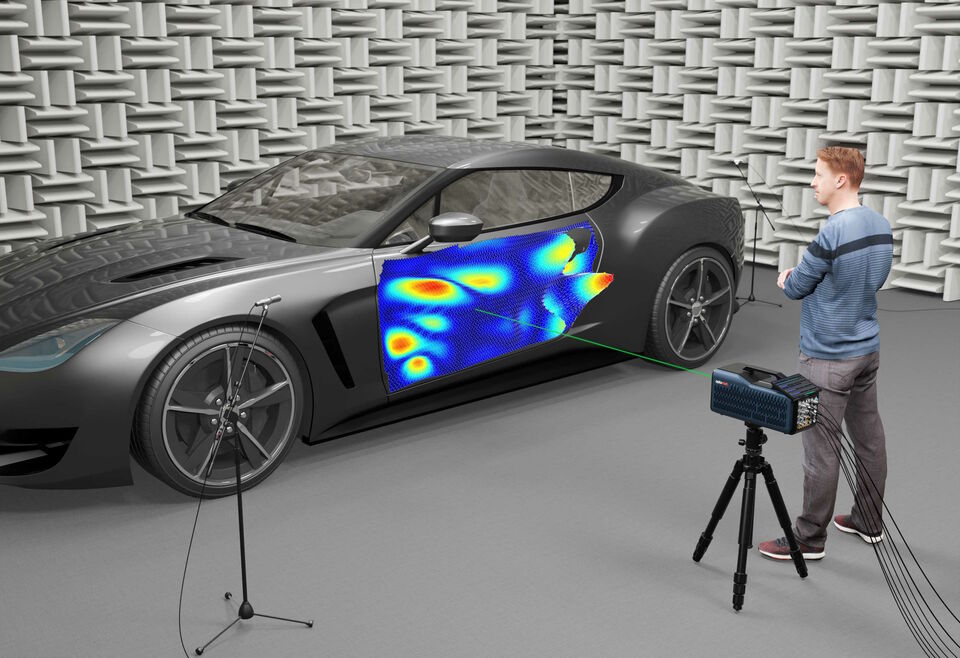

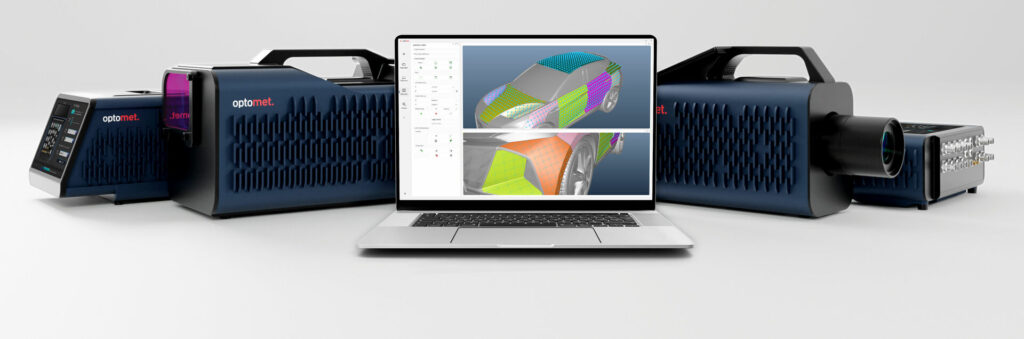

Our laser Doppler vibrometers set new standards in vibration analysis. Thanks to the non-contact measurement principle, even the finest movements and vibrations can be recorded with the highest precision. Whether in the automotive, aerospace or medical technology industries, our solutions are versatile and meet the highest metrological requirements.

Thanks to the combination of state-of-the-art laser sources and interferometer technologies, measurements can be performed on a wide variety of surfaces and under demanding conditions. The result: reliable data for informed decisions in research, development and quality assurance.