One-Stop Provider for Stress and Strain Measurement Products.

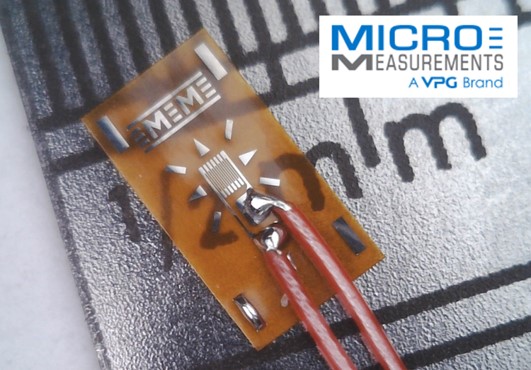

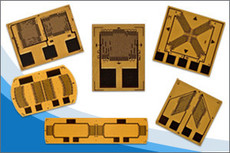

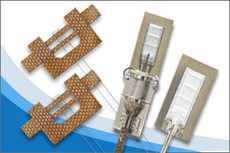

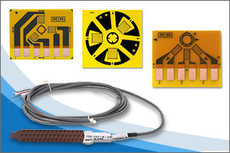

Micro-Measurements, a Vishay Precision Group, Inc. (VPG) brand, is dedicated to the development, manufacture, and marketing of resistive-foil sensors for high-precision strain measurement. Micro-Measurements offers a full complement of strain gages (gauges), PhotoStress® equipment and coatings, data acquisition systems, and gear necessary to obtain accurate, reliable stress data. Our products are used throughout the world — both in the practice of stress measurements analysis and as the sensing elements in a wide variety of transducers for measuring physical variables (weight, force, torque, pressure, etc.).

Read more