Training customers in the proper use of strain measurement techniques is an essential part of the Micro-Measurements philosophy. At Quantify we take over this philosophy as we want you to feel confident that you get quality data out of your measurements! And after all, getting quality data out of your measurements is the reason why we all start performing tests in the first place, right?

With our trainings, the products of VPG Micro Measurements, our cooperation with the British Society for Strain Measurements (BSSM) and their Code of Practice we hope to contribute to define a quality standard on the market for all strain gauge based installation techniques.

And so, Strain Academy was born!

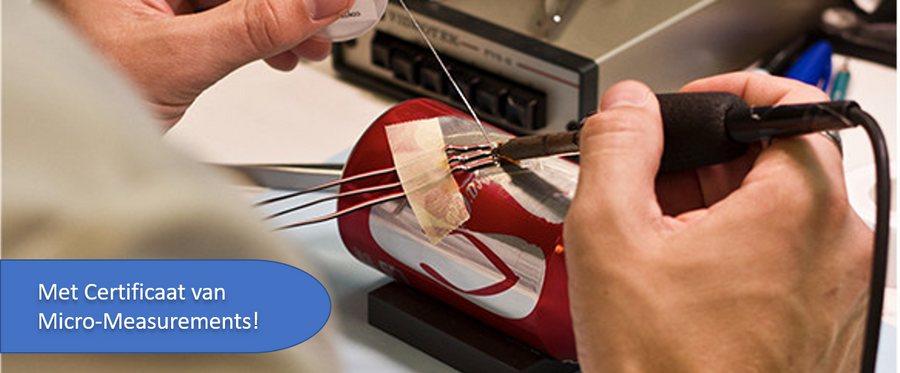

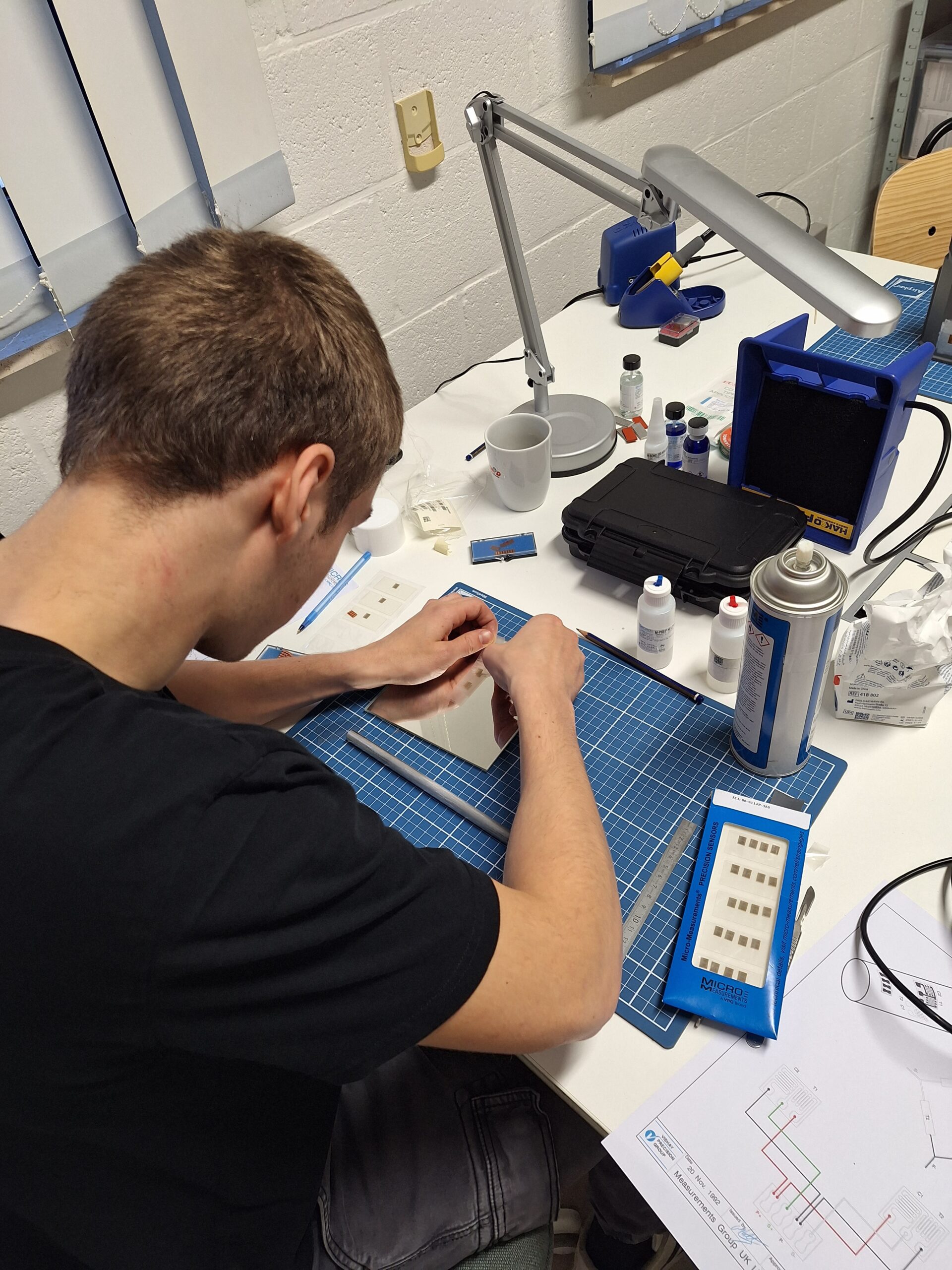

In this comprehensive, hands-on workshop, participants make several complete strain gauge installations, including electrical connections, check-out, and environmental protection; and use appropriate readout instrumentation to verify results of their own installations.

During this training the participants will learn how to bring a strain gauge installation to a good end with the confidence that what has been installed will produce quality data.

Focus is on mastering the right techniques, starting from a blank material, participants learn to select the right surface preparation, strain gauge, adhesives, soldering, cables and coatings.

In between the hands-on training, all topics that are crucial for understanding strain measurements will be reached out to the participants in depth. Going from temperature compensation over strain gauges circuitry to bridge excitation optimization and installation calibration.

The techniques, products and instruments used during our workshop are these employed and manufactured by VPG – Micro-Measurements.

Where : Quantify bv – Leuvenselaan 172, 3300 Tienen

When : 25 and 26 February 2025

Schedule: both days from 9:00 to 17:00

Trainer: Philippe Zwaenepoel – BSSM certified trainer

Language : French

Book via info@strainacademy.eu

The pre-exam seminar is normally taken in conjunction with the Level 1 exam but can be attended without taking the exam.

It is designed primarily for candidates who are taking the certification examinations (at any level) and is effectively a practice run of the exam, allowing the candidates to practice with the help of skilled tuition. They get help and tips on exam technique, and through the self assessment of their work, get a better understanding of the criteria on which they will be assessed. The seminar is not designed to teach the candidates how to do things, such as soldering techniques, but is intended as a technique perfection session.

The person who runs the seminar is an experienced examiner, and is able to help the candidates in a relaxed atmosphere. It has been found that candidates who take the optional seminar generally perform better in the examination.

The purpose of the Level 1 exam is to enable candidates to demonstrate that they use procedures that are in line with the Code of Practice, and that they are able to install meters according to BSSM standards.

The exam consists of two parts:

The practical test forms the main part of the exam and for this, candidates must choose one of two standard installations to complete:

(a) Stretch strips for quarter-bridge operation at a temperature between 0°C and 50°C.

(b) Full bridge of film meters for long-life operation at a temperature between 0°C and 50°C.

The written test consists of 20 multiple-choice questions based on general knowledge related to strain measurement and points that may arise during an installation. Candidates taking a second practical test are not required to take a second written test.

Where : Quantify bv – Leuvenselaan 172, 3300 Tienen

When : 18 and 19 June 2025

Schedule: both days from 9:00 to 17:00

Trainer: Philippe Zwaenepoel – BSSM certified trainer

Language : English

Book via info@strainacademy.eu